Digital Printing

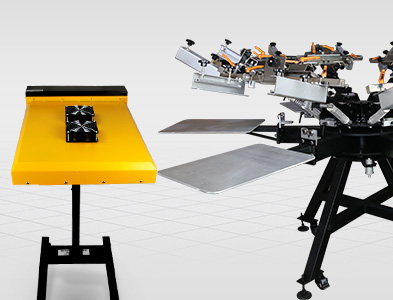

Screen Printing

₱1,120.00

FEATURES

RECOMMENDED FABRICS 100% Cotton Cotton/Polyester Blends Some 100% Polyesters INK APPLICATION Metallic Shimmers should be used right from the container without any modifications ADDITIVES If modification is necessary, use 1% to 5% by weight Sentri Clear - 3816 SCREEN MESH 86-110 t/in (34-63 t/cm) monofilament EMULSION Any direct or indirect emulsion or capillary film. SQUEEGEE 60-70 Durometer Sharp edge CURE TEMPERATURES 325ºF (163ºC) for 1 minute dependent on dryer speed and temperature settings CLEAN-UP Any eco-friendly plastisol screen wash STORAGE OF INK CONTAINERS 65º to 90ºF (18ºC to 32ºC)Avoid storage in direct sunlightKeep containers well sealed

1 in stock