Digital Printing

Screen Printing

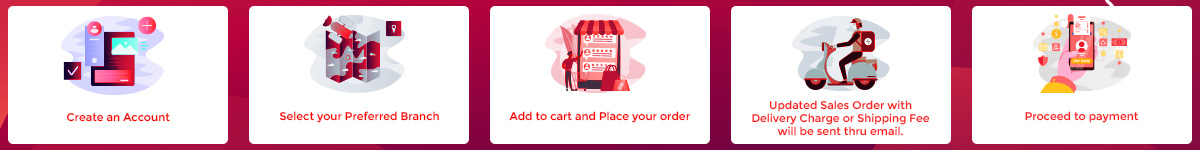

Online shopping is not available at this moment. Please go to the nearest store in your area. Dismiss

Skip to content

₱762.00

FEATURES

Out of stock

SPOT FLASHING

717 Ultimate Black™ will spot dry, with a very low after flash tack. Dwell time is dependent on the spot dryer used. In some cases, you may have to lower the heat of the spot cure unit because too much heat may actually make the ink tacky. When you spot dry, you are only partially fusing or gelling the surface of the ink. The ink should be just dry to the touch, with no lift-off, but not totally fused. Final fusing or curing should occur in the dryer.

IMPORTANT INFORMATION

717 Ultimate Black™ was formulated to make printing opaque black easy, so hand printing is less tiring. The result is improved operator performance. Automatic equipment can be adjusted to lower pressure settings, thus improving screen life and squeegee durability.

717 Ultimate Black™ prints so easily that a finer screen mesh can be used to achieve the same opacity as what you would expect from other opaque black inks at lower mesh counts.

717 Ultimate Black™ is not a color-mixing black ink.

Fibrillation can occur when printing on some cotton fabrics, especially when printing through finer mesh counts.

Adding any reducers or additives can lower bleed resistance, reduce opacity, or increase cure times of the ink. Stir the ink prior to printing on press and after addition of reducers or additives.

Test dryer temperatures and wash test printed product before and during a production run.

717 Ultimate Black™ will spot dry, with a very low after flash tack. Dwell time is dependent on the spot dryer used. In some cases, you may have to lower the heat of the spot cure unit because too much heat may actually make the ink tacky. When you spot dry, you are only partially fusing or gelling the surface of the ink. The ink should be just dry to the touch, with no lift-off, but not totally fused. Final fusing or curing should occur in the dryer.

Screen Printing Inks

Screen Printing Inks

Other Screen Printing Consumables

Screen Printing Inks

Screen Printing Inks

Screen Printing Inks

Screen Printing Inks

Screen Printing Inks