Digital Printing

Screen Printing

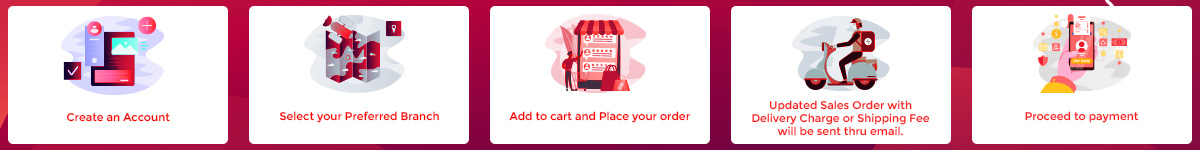

Online shopping is not available at this moment. Please go to the nearest store in your area. Dismiss

Skip to content

₱909.00

FEATURES

1 in stock

IMPORTANT INFORMATION

7100 Performance Pro™ Series is low fusing (low curing) plastisol. The recommended minimum cure temperature is 275°F (135°C). It is important to ensure that the ink is completely cured/fused before beginning production. Although a minimum of 1 minute is recommended, the time required for the ink to fuse completely will vary depending on the type of dryer used.

The use of additives such as stretch or reducers with 7100 series may inhibit the low bled and / or low fusing characteristics of this product.

Always test print the fabric to be used before beginning production to see if the desired performance is obtained. Wait at least 24 hours, longer if possible, before determining dye migration and bleed resistance.

Test dryer temperatures and wash test printed product before and during a production run.

IMPORTANT STORAGE INFORMATION

The fact that 7100 Series is a low fusing plastisol makes this product extremely sensitive to heat. Its shelf life may be shortened significantly if ink is left open and exposed to the average room temperature of a typical screen printing production floor for more than 12 hours. This product will tend to thicken or semi-gel if left in a screen or uncovered in the container over several days. For this reason it is vital that all unused ink be returned to the bucket and the lid be completely sealed. It is also important that ink containers be stored in the coolest area of the shop floor. Following both of these directions will extend the shelf life of this product.

Screen Printing Inks

Screen Printing Consumables

Screen Printing Inks

Other Screen Printing Consumables

Screen Printing Inks

Screen Printing Inks

Screen Printing Inks

Screen Printing Inks